Top quality is our duty, sustainability is our goal

The GUTMANN Group traces its history back to 1937. That was when the founder, Hermann Gutmann, established the H. Gutmann light metal wire foundry in Weissenburg, Germany, laying the cornerstone of today’ globally active company, which sees innovation and quality awareness not as an end in itself, but as a means to achieving full customer satisfaction. Working in partnership and with a focus on solutions, the company continuously improves quality and services, without losing sight of cost optimisation.

Certified Quality

We never stop working to raise our standards. Being good inspires us to become even better. Our internal quality assurance system guarantees that only flawless components are sent on to the next processing step. The result: highly precise and functional products, which can be incorporated smoothly into our customers’ manufacturing processes.

We also continuously monitor all our services, as well as our own specialist and social expertise, in order to improve our products and ourselves as a company.

A holistic approach

As far as we are concerned, we are responsible for our employees, the environment and society. Training and professional development are an integral part of our philosophy. We believe that open communication and information encourage trust, personal responsibility and proactive employees.

Resource-saving production

We are committed to ensuring resource-saving production with a production and material cycle that is as self-contained and loss-free as possible, and we have implemented an energy management system in accordance with DIN EN ISO 50.001.

Any aluminium scrap accumulated during manufacturing is melted down in our own remelting facility. In the subsequent casting process, high-quality aluminium billets are created for the production of our aluminium profiles.

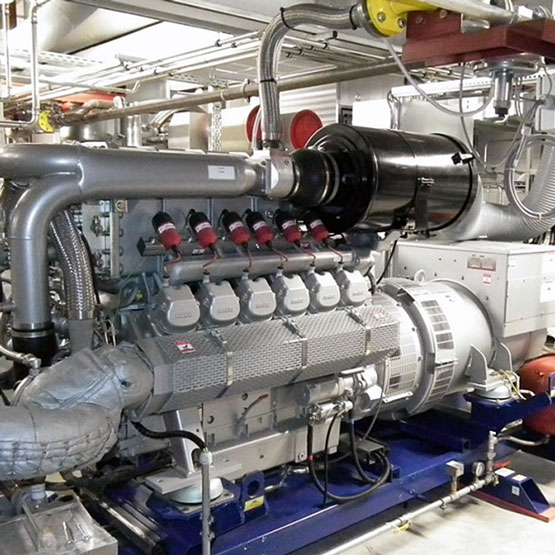

In addition, GUTMANN GmbH has been operating its own combined heat and power plant since April 2014. This allows the energy used to be used twice thanks to the trigeneration process (combined cooling, heat and power (CCHP)): once for generating power, and again for heating and cooling. The reductions this makes possible in carbon dioxide and nitrogen oxide emissions speak for themselves.

A/U/F – a shared objective

Using innovative technologies to protect the environment, save resources, improve quality of life and work more efficiently: this is what A/U/F is all about. This collaboration between system vendors, fabricators and suppliers in the aluminium sector promotes a future-oriented and environmentally conscious approach to aluminium. Recycling of old aluminium windows, doors, curtain walls and the corresponding composite products, such as wood-aluminium windows, emphasises a commitment to sustainability. A/U/F ensures a qualified material cycle for aluminium in both Germany and Europe.