Aluminium sets standards in mechanical engineering with high precision, modern design, and extreme durability. These complex properties, in combination with great corrosion resistance, may be accurately adapted to individual applications. Progressive tool technology allows users to develop a powerful product at economical prices.

GARTNER EXTRUSION GmbH manufactures cylinder and piston profiles for pneumatic cylinders.

What makes this mechanical application so special is its low construction height resulting from the oval design. In this case, aluminium ensures extreme long-term durability. The material also meets the requirements for tight tolerances, narrow details, excellent cutting properties, corrosion resistance, and modern design.

During the modernization of its manufacturing area, a customer of GARTNER EXTRUSION GmbH switched the production of folding rulers from casting to extrusion profiles. Now even small quantities in different variations can be manufactured cost-effectively. The requirements of tolerances during extrusion are just as high as they are for processing and surface quality of the aluminium profile.

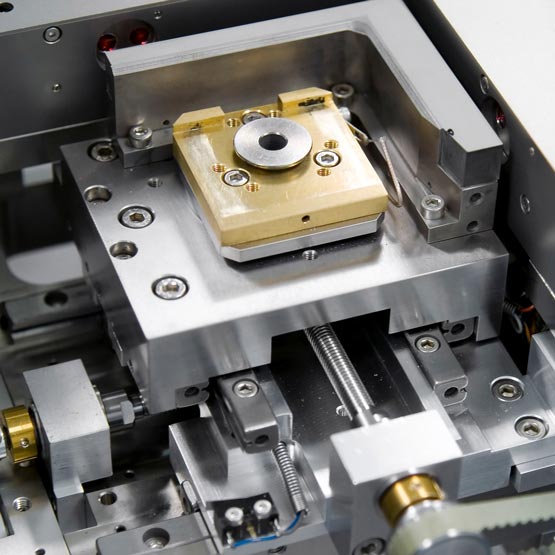

GARTNER EXTRUSION GmbH manufactures pneumatic drives for various applications in automation technology. The cylinder profile without piston rods manufactured by Gartner ensures high performance even in the smallest of spaces. The aluminium profiles must have extreme tolerances, low coarseness in cylinder drilling, durability, and a modern design. Anodizing reduces wear and tear, especially from mechanical abrasion.

In Weissenburg, GUTMANN AG manufactures aluminium profiles used as frame profiles for cooling devices in track vehicles. The aluminium profiles are especially suitable for this purpose as they conduct heat well. For the welded structure, elaborate CNC-processing is necessary.