Today, many people focus on individuality and self-realization. GUTMANN in Weissenburg has now adapted its well-established DECCO system to the new Rehau ARTEVO profile to suit customers who want to enjoy the benefits of PVCu windows but also have the highest standards of architectural design. The edged look of the PVCu system from Rehau, which is also continued in the aluminum facing shell, is particularly noteworthy.

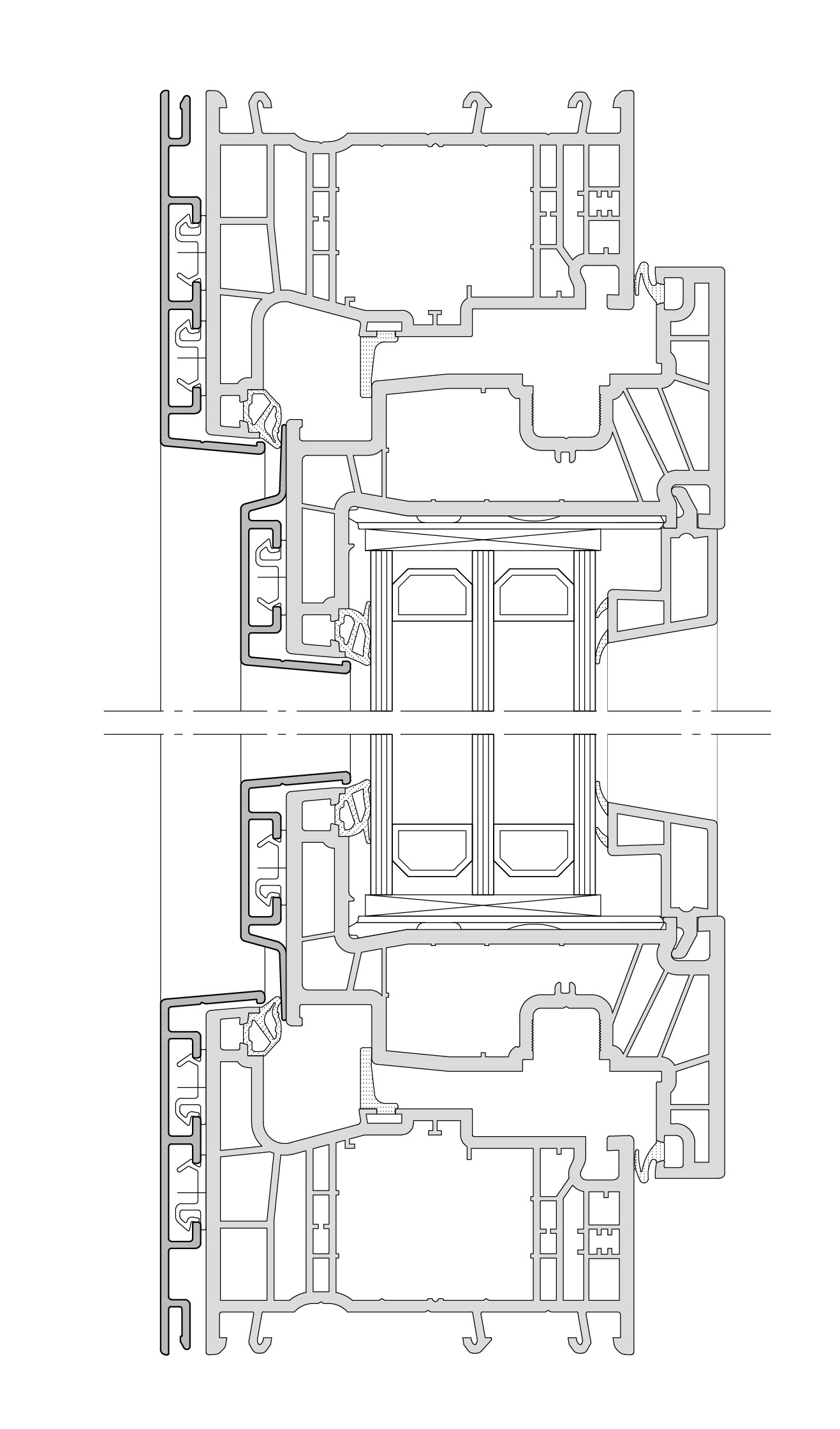

The DECCO ARTEVO PVCu/aluminium system is specially designed to absorb the different temperatures caused by sunlight by using clip holders. Dark shades on the outside in particular heat up more than light colors and can lead to uneven expansion. The combination of plastic and aluminium minimizes this effect, resulting in improved stability and durability of the construction. The end-coupled mounting of the aluminum profiles using clip profiles and holders also counteracts temperature-related linear expansion.

With the perfectly tailored aluminium cover, there are virtually no limits to the design. Whether powder-coated or anodized, GUTMANN DECCO ARTEVO powered by REHAU adapts to any colour concept. The entire GUTMANN color spectrum from RAL and NCS is available, as well as decorative and special colors. More about colors on our website GUTMANN Farbenwelt.

GUTMANN DECCO ARTEVO gives windows an individual look and also protects the PVCu profile from the effects of weather and UV radiation, thus extending its service life.

Easy installation

Installation is extremely simple: DECCO is available fully prefabricated on request to fit the existing PVCu window. The DECCO frame arrives at the place of further use as a welded or plugged version with the previously defined surface coating. Here, the aluminum profiles can be easily applied using the established cold welding process patented by GUTMANN. Alternatively, the newly introduced screw or impact clips from GUTMANN can be used for a secure connection.

Welded corner connections of the aluminum cover shell offer numerous advantages, such as an even distribution of loads, a high-quality and professional appearance and improved durability compared to other connection methods. They also enable easy assembly and disassembly, reduce the risk of leaks and damage, offer a precise fit, optimum heat conduction, high load-bearing capacity and are resistant to corrosion. Overall, welded corners contribute to an aesthetic appearance and a durable construction. The design is also easy to clean, which makes maintenance easier.

- The edged look of the PVCu system is also continued in the aluminum cladding

- Aluminum profiles for the new generation of PVCu windows

- The window remains in the standard production line during DECCO installation

- No specialized production, ready-made aluminium frames are supplied

- Low installation effort thanks to the innovative cold welding process patented by GUTMANN

- As an alternative to the cold welding process, installation can be carried out using screw or impact clips

- Available as finished frames in plugged and welded versions

- Welded corner joints with a high-quality, robust look and no visible butt joint

- Uniform external appearance for properties with different window materials (wood, PVCu, aluminum)

- High-quality exterior appearance thanks to a wide range of color combinations and variations; all RAL, NCS, decorative and special colors are available

- In addition, the supply of coated or blank profiles and aluminium frame production by the window manufacturer is also possible

- End-coupled mounting of the aluminium profiles using clip profiles & holders to absorb temperature-related linear expansion

GUTMANN Catalog DECCO ARTEVO

Construction Data (CAD files) - Profiles

- 520043.dwg [dwg / 202 KB]

- 520125.dwg [dwg / 202 KB]

- 540012.dwg [dwg / 203 KB]

- 540015.dwg [dwg / 203 KB]

- 540021.dwg [dwg / 203 KB]

- 540038.dwg [dwg / 203 KB]

- 540041.dwg [dwg / 205 KB]

- 540072.dwg [dwg / 204 KB]

- 540080.dwg [dwg / 204 KB]

- 540084.dwg [dwg / 204 KB]

- 540088.dwg [dwg / 204 KB]

- 540121.dwg [dwg / 204 KB]

- 540131.dwg [dwg / 205 KB]

- 540133.dwg [dwg / 204 KB]

- 540238.dwg [dwg / 203 KB]

- 540277.dwg [dwg / 203 KB]

- 550516.dwg [dwg / 227 KB]

- 551046.dwg [dwg / 222 KB]

- 551047.dwg [dwg / 218 KB]

- 551048.dwg [dwg / 221 KB]

- 551248.dwg [dwg / 225 KB]

- 552382.dwg [dwg / 214 KB]

- 552501.dwg [dwg / 211 KB]

- 554307.dwg [dwg / 215 KB]

- 556877.dwg [dwg / 214 KB]

- 556878.dwg [dwg / 215 KB]

- 556879.dwg [dwg / 215 KB]

- 556880.dwg [dwg / 214 KB]

- 556895.dwg [dwg / 313 KB]

- 556899.dwg [dwg / 316 KB]

- 556900.dwg [dwg / 319 KB]

- 556901.dwg [dwg / 321 KB]

- 556902.dwg [dwg / 314 KB]

- 556903.dwg [dwg / 316 KB]

- 556905.dwg [dwg / 316 KB]

- 570002.dwg [dwg / 203 KB]

- 570114.dwg [dwg / 206 KB]

- 570145.dwg [dwg / 206 KB]

- 570147.dwg [dwg / 205 KB]

- 580616.dwg [dwg / 203 KB]

- 580700.dwg [dwg / 204 KB]

- 580745.dwg [dwg / 204 KB]

- 581949.dwg [dwg / 209 KB]

- 583042.dwg [dwg / 209 KB]

- 583043.dwg [dwg / 209 KB]

- 583044.dwg [dwg / 211 KB]

- 583687.dwg [dwg / 215 KB]

- 583693.dwg [dwg / 214 KB]

- 584024.dwg [dwg / 208 KB]

- 584204.dwg [dwg / 209 KB]

- 584205.dwg [dwg / 209 KB]

- 584535.dwg [dwg / 214 KB]

- 584536.dwg [dwg / 211 KB]

- 585533.dwg [dwg / 209 KB]

- 585534.dwg [dwg / 212 KB]

- 585535.dwg [dwg / 211 KB]

- 585997.dwg [dwg / 206 KB]

- 588669.dwg [dwg / 219 KB]

- 593924.dwg [dwg / 226 KB]

- 595267.dwg [dwg / 215 KB]

- 595847.dwg [dwg / 226 KB]

- 596044.dwg [dwg / 212 KB]

- 596133.dwg [dwg / 217 KB]

- 596134.dwg [dwg / 223 KB]

- 596173.dwg [dwg / 216 KB]

- 596180.dwg [dwg / 224 KB]

- 596692.dwg [dwg / 260 KB]

- 597310.dwg [dwg / 209 KB]

- 597311.dwg [dwg / 209 KB]

- 597405.dwg [dwg / 232 KB]

- 597512.dwg [dwg / 217 KB]

- 599233.dwg [dwg / 206 KB]

- 599491.dwg [dwg / 240 KB]

- 599987.dwg [dwg / 227 KB]

Construction Data (CAD files) – Cross Section Points & Processing Guidelines

- K 04032.dwg [dwg / 411 KB]

- K 04033.dwg [dwg / 386 KB]

- K 04034.dwg [dwg / 412 KB]

- K 04035.dwg [dwg / 417 KB]

- K 04036.dwg [dwg / 398 KB]

- K 04037.dwg [dwg / 364 KB]

- K 04038.dwg [dwg / 393 KB]

- K 04039.dwg [dwg / 407 KB]

- K 04040.dwg [dwg / 362 KB]

- K 04041.dwg [dwg / 395 KB]

- K 04042.dwg [dwg / 361 KB]

- K 04043.dwg [dwg / 388 KB]

- K 04044.dwg [dwg / 360 KB]

- K 04045.dwg [dwg / 373 KB]

- K 04046.dwg [dwg / 375 KB]

- K 04047.dwg [dwg / 353 KB]

- K 04048.dwg [dwg / 454 KB]

- K 04049.dwg [dwg / 402 KB]

- K 04050.dwg [dwg / 386 KB]

- K 04051.dwg [dwg / 385 KB]

- K 04101.dwg [dwg / 1 MB]